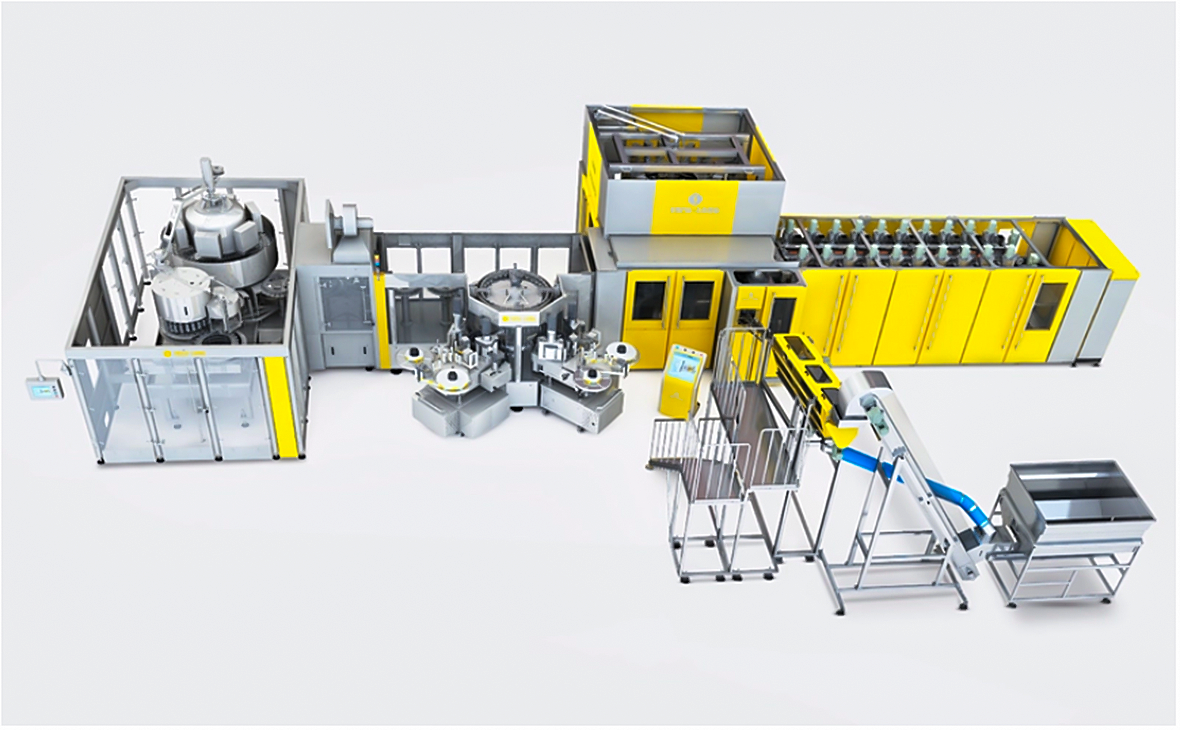

Blowing labeling filling capping monobloc for water bottle & soda filling

As the rarer Blfc Monoblock Machine suppliers who has the key technology of PET blower and filler, TECH-LONG is the pioneer of monobloc machine. Our Blowing-Labeling-Filling-Capping monobloc machine (BLFC Monobloc Filling machine) efficiently integrates blow molding, labeling, filling and capping machines in one block, which is the most advanced technology for water bottle filling and soda filling.

BLFC Monoblock Machine

Technical data

| Number of moulds/bottle rotation assemblies/filling valves/capping heads | 20×36×60×24 | Bottle diameter range (mm) | Φ40~Φ80 |

| Rated capacity (BPH) | 48,000 | Bottle volume range (ml) | 200~750 |

| High-pressure air consumption (nm³/min) | 9.8 (30bar) 8.2 (25bar) | Bottle height range (mm) | 150~320 |

| Installed power (kw) | 438 | Label width range (mm) | 30~175 |

| Dimension (mm) | L21257 × W9270 × H3560 | Label length range (mm) | 138~266 |

| Gross weight (T) | 35.2 | Distance range from label to bottle bottom (mm) | 35~115 |

BLFC Monoblock Machine

Product advantage

Capacity 48000BPH

Fewer operators

Compatible with various bottle sizes

Up to 98% equipment efficiency with MES

intelligent management system

Equip visual inspection & ejection system

A fast and accurate detection of empty bottles, cap seal, and

filling level, and quick ejection of defective products with

advantages of fast speed, high accuracy, stable operation and etc.

BLFC Monoblock Machine

Product Details

Blower main features

● Servo stretching and mechanical seal structures work to realize flexible adjustment of relative parameters, as well as maximum processing angle.

● Base mould is interlock with mould opening and closing mechanism, which reduces strike and vibration.

● Blowing technology with 6 blowing units to reduce high pressure air consumption by 40%~55%.

● Quick changeover of neck finish and bottle body size parts to better fit bottles of various formats.

● The high-speed heating and air circulation system can save over 40% in energy consumption.

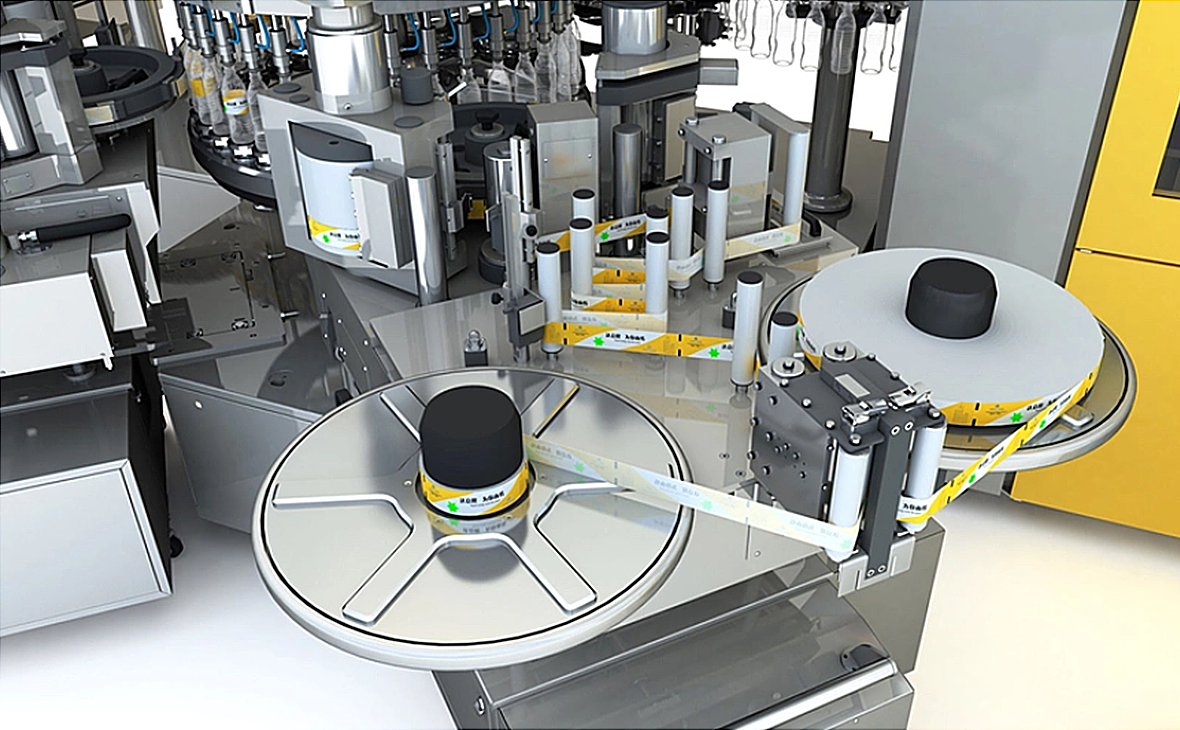

Labeling design features

The machine integrates bottle blowing, labeling, and capping into a single system, and is transported through a bottle clamping mouth to minimize equipment damage to the bottles. The labeling machine is located behind the bottle blowing machine and labels empty bottles through a bottle clamp.

Filling-capping features

● Double layers explosion proof toughened glass is fixed on floor-stand enclosed frame, which makes the machine well-protected, aesthetically pleasing and prevents fogging.

● Inclined basement design to obtain best drainage capability, which is more sanitary.

● Volumetric filling method via flow meters is both economic and durable.

● Easy changeover of filling products without return process ensures energy saving and hygienic results.

● Fully automatic enclosed and circulating CIP system for high efficiency and optimum hygiene.

● Optimized and flexible track for capping cam can assure stability during high speed rotation.

Get in touch with us

Would you like to ask us a question, are you looking for a contact person or do you need help with a problem? Then simply fill in our contact form.

We will get in touch with you as soon as possible.

Reviews

There are no reviews yet.